Advantages of laser drilled leak test holes include:

> Better resemble natural defects in glass (cracks) and polymers (pinholes).

- > Tight tolerances can be achieved in most material and thicknesses.

- > Hole diameter sets and calibration packages can be customized based on customer requirements.

- > A Certificate of Conformance and Quality Data Sheet is included with each Leak Test Hole Drilling Order.

- > Leak test holes as small as 1 micron

- > Accurate leak hole placement

- > Expedited delivery if required.

- > Our measurement equipment is calibrated utilizing a NIST traceable standard.

We can laser drill calibrated micro holes in many different types of containers including vials, syringes, pouches, and any type of bags. Common container conditions include whether it is open or closed and whether it is empty or pre-filled.

The existing FDA and other regulations tend to adopt the deterministic method. The purpose of our laser drilling is to test the complete sealing of the packaging container by vacuum attenuation method in order to meet the testing requirements. The purpose is to help customers pass the EU certification and FDA review.

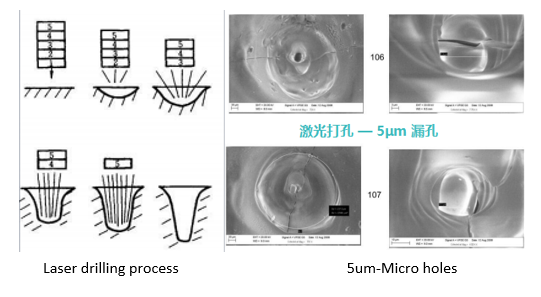

Laser drilling is the best way to get close to the shape and morphology of the leaky holes and cracks occurring in nature. The leaky holes can be measured and verified by microscopy and velocity comparison.