CCIT Positive controls

How to be sure that the machines responsible for detecting these imperfections are calibrated correctly to guarantee they will pick up every damaged part?

Positive controls with calibrated leaks ensure that your leak testers are working properly, and that the testers are able to find even the most challenging leak artifacts.so that pharmaceutical companies can monitor and verify that their inspection systems meet proper quality standards.

We are a leader in providing Positive Controls used for test method development and validation. Call on us today to help you with your CCIT needs.

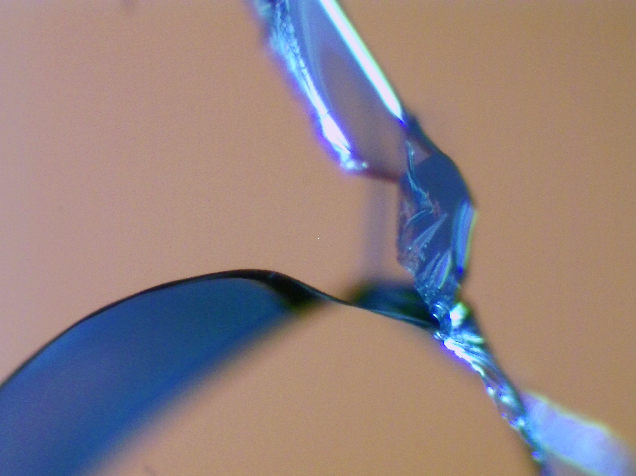

>> Laser Drilling

The existing FDA and other regulations tend to adopt the deterministic method. The purpose of our laser drilling is to test the complete sealing of the packaging container by vacuum attenuation method in order to meet the testing requirements. The purpose is to help customers pass the EU certification and FDA review.

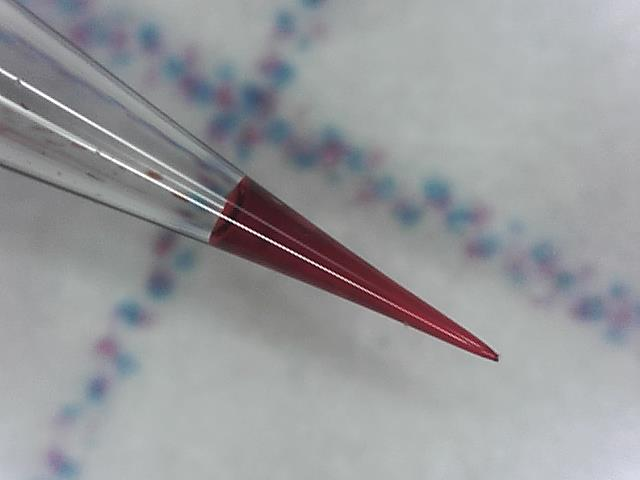

>> Micropipette

The pipette's aperture can be as low as 0.1μm, but the tip is very fragile, so it is easy to be damaged in the process of sample preparation. It is necessary to be careful of the tip damage when preparing, and ensure that the pipette's surrounding seal is intact after implantation.

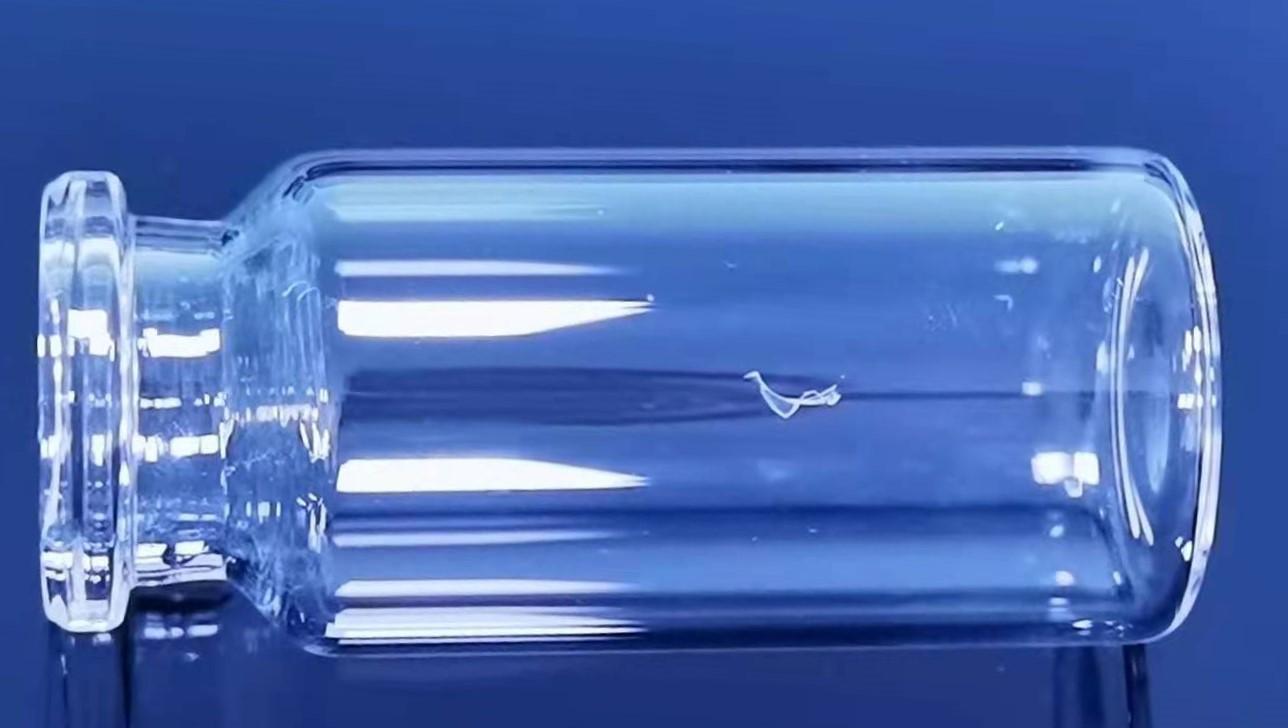

>> Natural defects

Natural defect is a new type of positive sample that is the nearest to the actual glass crack prepared by artificial way. It is suitable for the packaging materials of conventional glass materials such as penicillin bottles and ampoule bottles. The aperture of natural defect can be less than 1 micron.

>> Capillary

Capillaries are made of quartz material with a molten polymer coating. They are strong and flexible, and can be inserted into a variety of packaging materials, from plastic plugs to plastic glass, to simulate pores as small as 1μm or less.

PREPARATION METHODS OF POSITIVE CONTROL SAMPLES

Shanghai Zillion M&E Equipment Co.,ltd E-mail:info@zillionccit.com Tel:4008880570 Add:9 / F, building 11, No. 518 xinzhuan Road, Shanghai | Privacy Policy |

Shanghai Zillion M&E Equipment Co.,ltd E-mail:info@zillionccit.com Tel:4008880570 Add:9 / F, building 11, No. 518 xinzhuan Road, Shanghai | Privacy Policy |